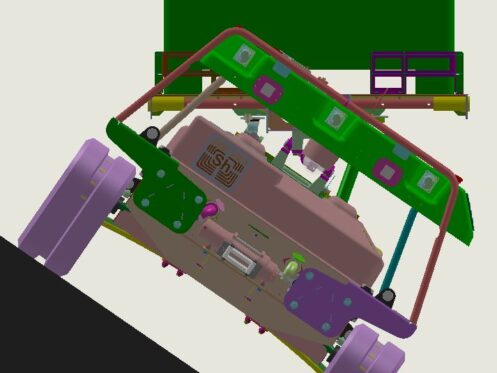

Base Platform

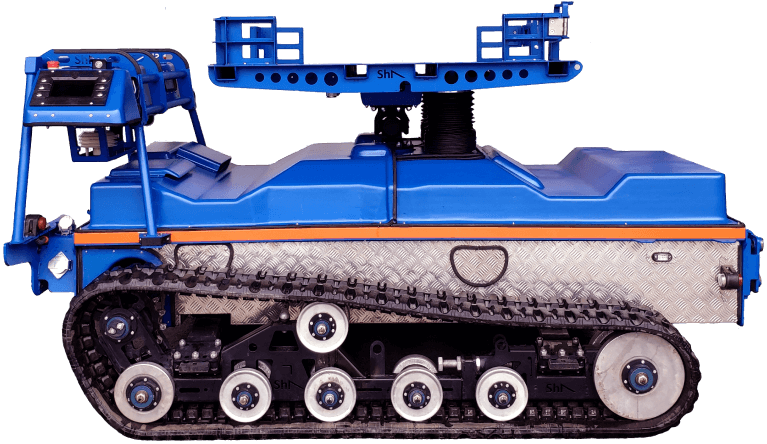

The Base platform is the core component of the Slopehelper autonomous robotic low-voltage electric agrosystem.

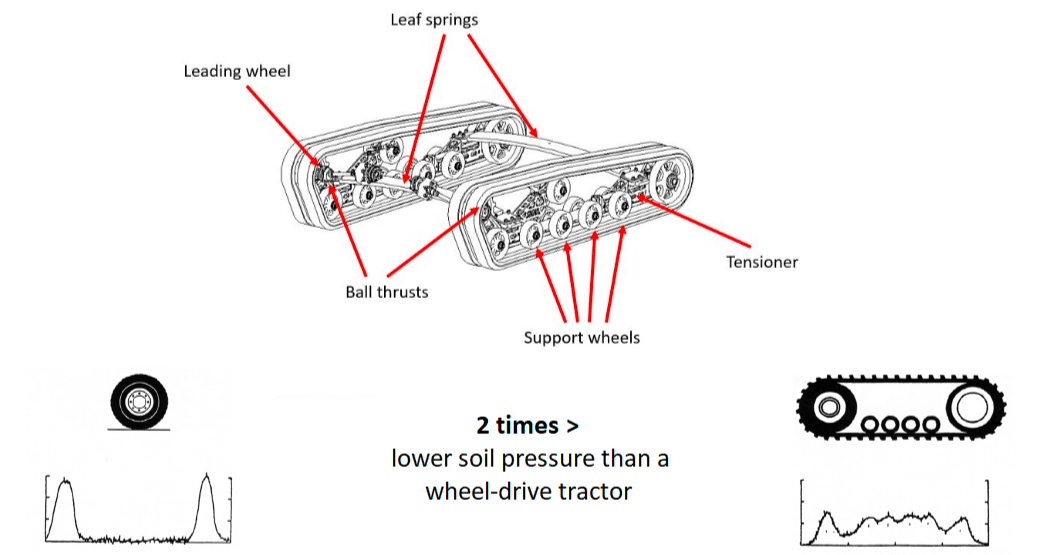

Base platform equipped with two suspended caterpillar blocks, it offers exceptional operational capabilities in all weather conditions, exerting 2 times less pressure on the soil compared to a conventional 120-horsepower tractor with low-pressure wheels.

The Base platform consolidates the transmission, electronics, power unit, and a versatile cargo platform designed for attachment with various hinged equipment. This equipment can be installed on the front, rear, side, or atop the cargo platform, making the Base platform a flexible foundation for any type of yearly agro-cycle operation.

A unique feature of the cargo platform, which is installed on top of the Base platform, is its gravity-stabilized design. This ensures stable operation of various equipment like harvesting shelves, sprayers, and fertilizers on inclined surfaces, enhancing efficiency and adaptability across different terrains and tasks.