Video Player is loading.

No more hand labor in agriculture

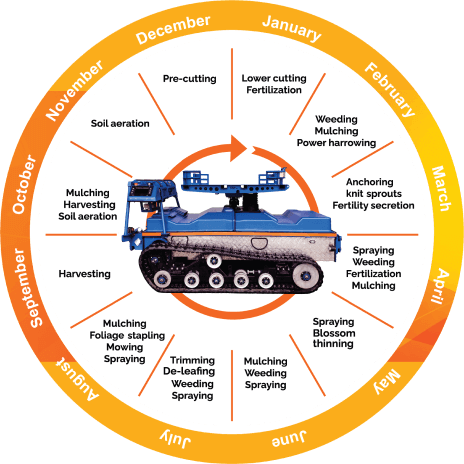

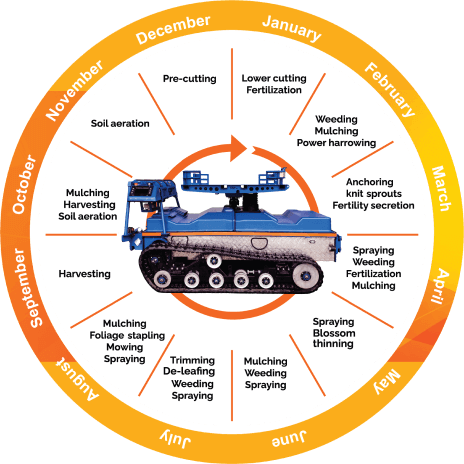

Exponentially superior to traditional agrosystems

- Entire

Agro – Cycle - Lower initial

investments - Triple lower costs

Embrace ease with slopehelper

- Automate workforce

- eradicate staffing

struggles - Forget about

worker’s costs

Embrace the future, not the worry

Slopehelper will meet state “Green” regulations

in your company without extra costs

It’s not the future, it’s present

Our technology kick-starts your company’s true

Agriculture 4.0 modernization now!

Current TimeВ 0:00

/

DurationВ -:-

Loaded: 0%

Stream TypeВ LIVE

Remaining TimeВ -0:00

В

1x

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

The media could not be loaded, either because the server or network failed or because the format is not supported.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

info@pekauto.com

+386-307-77-050

PeK Automotive d.o.o., Obrtniška ulica 17,

1370 Logatec, Slovenia

1370 Logatec, Slovenia

No more hand labor in agriculture

Exponentially superior to traditional agrosystems

- Entire

Agro – Cycle - Lower initial

investments - Triple lower costs

Embrace ease with slopehelper

- Automate workforce

- eradicate staffing

struggles - Forget about

worker’s costs