Slopehelper All-in-One Robotic System

Meet Slopehelper—the game-changing autonomous robotic agrosystem that replaces an entire fleet of traditional farming machines. Designed for effortless, round-the-clock operation, this low-voltage electric powerhouse transforms how you manage your fields, delivering unmatched efficiency, cost savings, and sustainability.

How Slopehelper Works

Everything you need to streamline your field agro operations with effortless simplicity. Simple, just like counting 1-2-3.

1. Charge the Base Platform

Charge the Base Platform at the Charging Station, ensuring full operational readiness.

2. Choose your Attachment

Secure the appropriate Hinged Attachment using the Installation Carrier for precise functionality.

3. Set it up and Start

Transport with a B-category trailer, set parameters, attach tools, and start. Monitor remotely via TeroAir.

Slopehelper: Features & Benefits

Slopehelper combines cutting-edge technology with advanced design to revolutionize agricultural operations. Below are its core features and benefits that make it essential for modern farming.

Slopehelper is equipped to handle agricultural tasks throughout the entire year, ensuring continuous productivity.

A complete autonomous solution that reduces labor dependency while maximizing efficiency in plantation management.

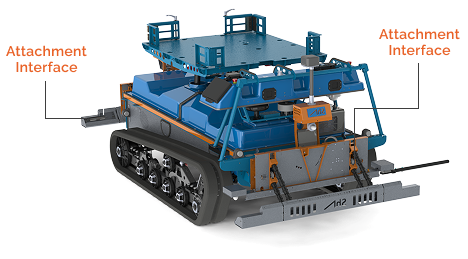

Integrates a robust base platform, advanced instruments, and state-of-the-art IT to enhance agricultural operations.

The first system to provide end-to-end support for every stage of the annual agricultural cycle.

Operate Slopehelper effortlessly by setting row numbers and operation parameters via an onboard computer and monitor progress on your smartphone.

Functions independently of GNSS using AI-powered sensors, including an Inertial Measurement Unit and radiolocator.

Designed to function reliably despite dust, rain, or poor satellite signal conditions.

Streams operational data and live video feed to the TeroAIR application for seamless tracking and management.

Charging time varies between 3.5 to 8 hours, using a safe, low-voltage connection for enhanced operational reliability.

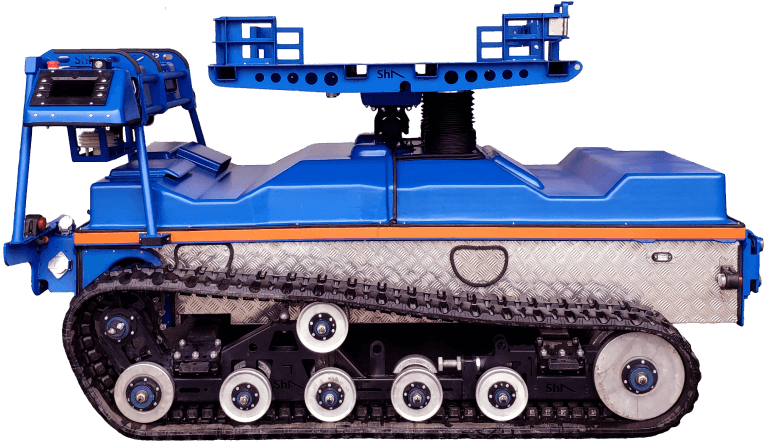

A highly efficient electric powertrain delivers strong traction while ensuring safety, simplicity, and energy efficiency.

Capable of handling inclinations of up to 42 degrees while operating continuously for up to 14 hours.

Compact and lightweight, Slopehelper can be easily transported using a standard car and trailer.

Designed exclusively for Slopehelper’s system, ensuring optimal feedback, autonomy, and safety in operations.

Features a mechanical brake and safety bumpers for secure operation, independent of electronic controls.

Fully electric design eliminates hydraulic systems, reducing maintenance and improving operational efficiency.

Implements are stored on specialized carriers and secured with simple screws, minimizing costs and setup time.

Engineered to navigate plantation passages smoothly, exerting low soil pressure to protect tree roots.

A robust 5-year or 8,000-hour warranty reflects Slopehelper’s durability and commitment to sustainable farming.

Represents the next step in plantation automation, integrating cutting-edge technology for superior efficiency.

Powered by electricity instead of fossil fuels, ensuring cost-effectiveness and eco-friendly operation.

Specifications

Explore Slopehelper’s full agrocycle capabilities with specialized attachments for every season. Click to see detailed specifications and discover how it transforms your vineyard or plantation year-round.

AGROCYCLE OPERATIONS

Soil Preparation & Maintenance

Weed Management & Mulching

Treatment & Protection

Prunning & Canopy Trimming

Leaves & Flowers Control

Deployment

Setting up the Slopehelper robotic agrosystem is a straightforward process that ensures reliable operation throughout the lifetime of the plantation. Once deployed, only minimal maintenance is required. The deployment involves three simple steps:

- Clearing the field of obstacles such as fallen trees, columns, broken wires, large stones, and earth mounds that may obstruct the passages.

- For plantations without metal pillars, installing reflectors at the beginnings of rows. Reflectors are inexpensive special plastic elements that are installed at the beginning of each row, providing radio locators with a reliable way to detect the start of each row. (Note: In most cases with metal pillars, this step is not needed.)

- Preparing a geometrical model of the plantation, which can be done either manually with a meter or by utilizing a mapping system.

Feasibility

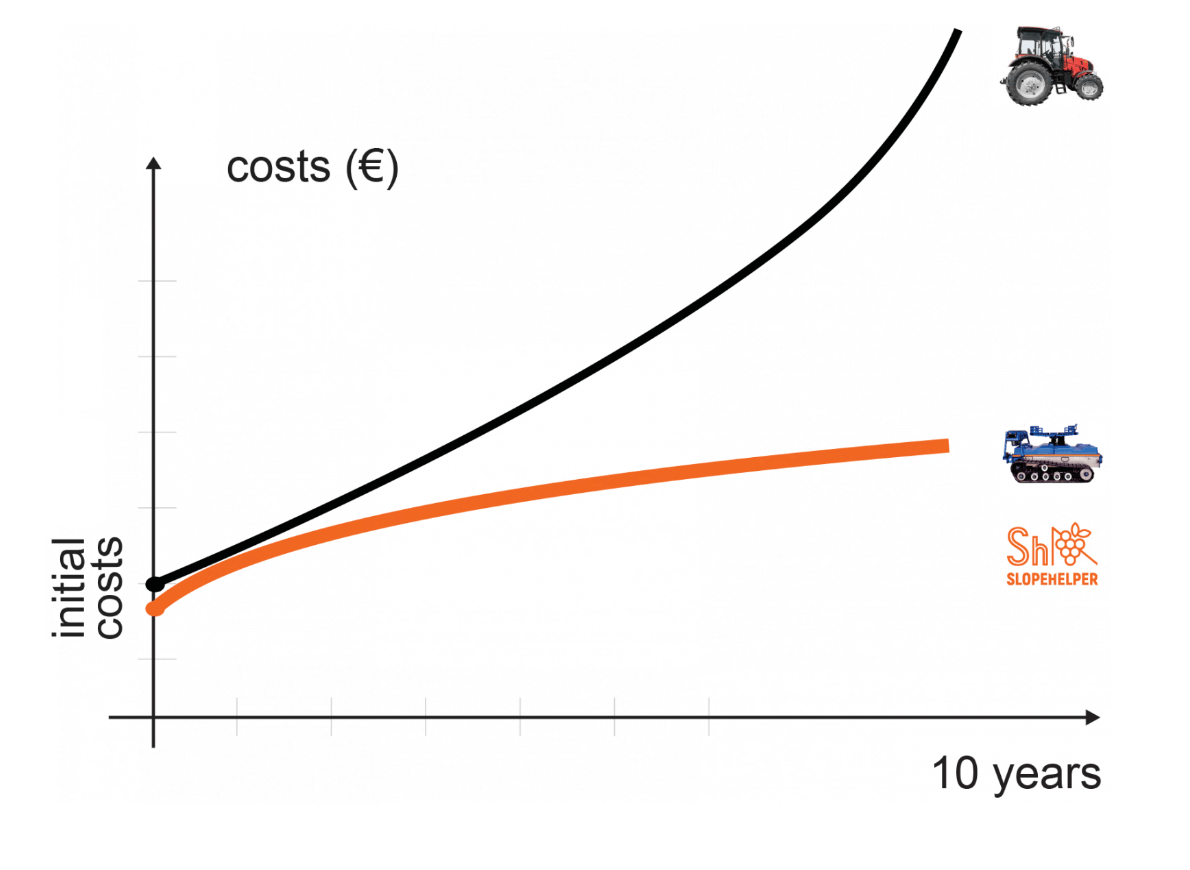

The Slopehelper is an autonomous robotic low-voltage electric agrosystem that offers amazing benefits in the agricultural sector. With up to three times lower cost efficiency and initial investments reduced by several tenths of a percent compared to conventional tractor-based agrosystems, it represents a significant advancement.

Furthermore, Slopehelper’s modular design allows for a gradual extension of Agrocycle operations. Owners can initially invest in essential equipment, and then progressively add additional hinged tools as needed to cover the entire agrocycle. This flexibility means that even the most critical operations can be addressed first, with the option to expand coverage over time.